Hollow Building Template CE Certificate Cost Saving UPVC Window and Door Profile Production Line Extrusion PVC Wall Panel Machine

Basic Info

| Model NO. | YF180 /240 /300 /400 /500 /600 |

| Assembly Structure | Integral Type Extruder |

| Screw | Twin-Screw |

| Engagement System | Full Intermeshing |

| Exhaust | Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| Production Name | PVC Window/Door Profile Extrusion/Making Machine |

| Application | PVC Window/Door Profile |

| Condition | New |

| Weight | 35000 Kg |

| Extrusion Max.Capacity | 300kg/H |

| Dimension | Customized |

| Max. Product Width(mm) | 600 |

| Max. Product Height(mm) | 150 |

| Key Selling Points | Automatic |

| Main Motor | Siemens |

| Certification | SGS CE |

| Brand Name | Sinotech |

| Twin Screw Type | Co-Rotating Conical Twin-Screw |

| Processing Type | Extruding Equipment |

| Function | Profile Producing |

| Transport Package | Wooden Base |

| Specification | CE, ISO |

| Trademark | sino-tech |

| Origin | China |

| HS Code | 8477209000 |

| Production Capacity | 100PCS/Year |

Packaging & Delivery

Package size per unit product 25000.00cm * 1700.00cm * 2300.00cm Gross weight per unit product 35000.000kgProduct Description

Product Description

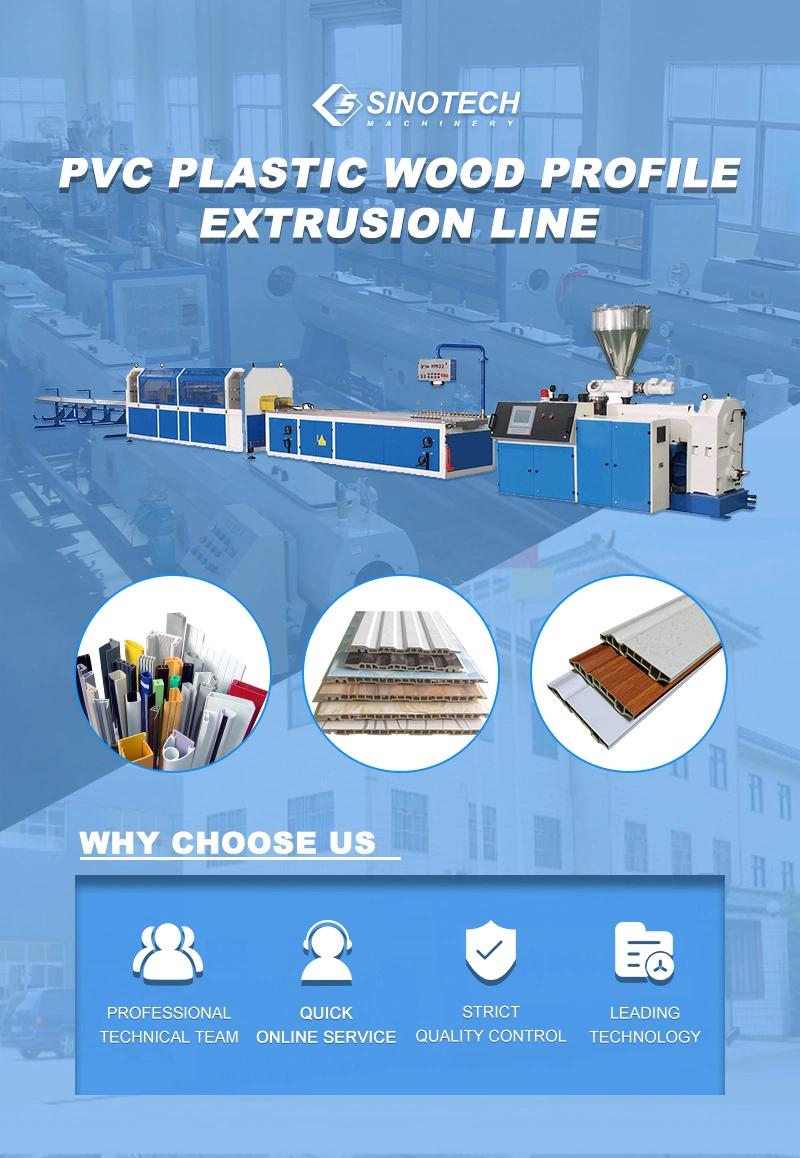

SINTECH PVC UPVC WPC Profile Extrusion Production Line

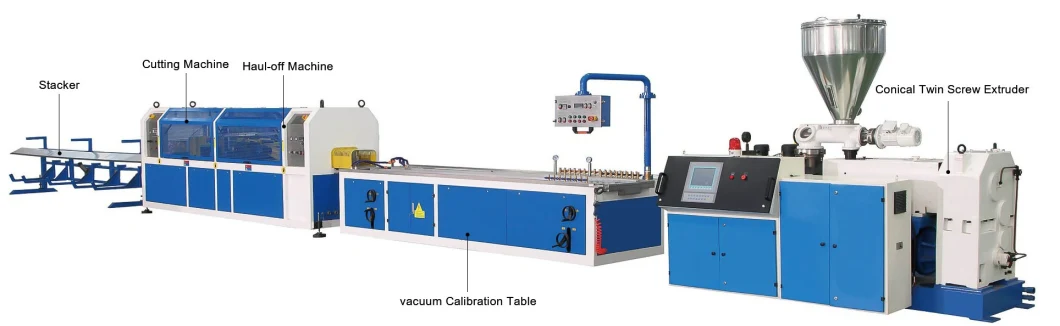

PVC profile making machine mainly composed by Conical Twin Screw Extruder, Cooling Table, Hauling Machine, Cutting Machine, Stacker. With different moulds, it can produce various UPVC profile, such as: PVC window door profile, PVC wall panel, PVC window sill board, cabinet door board, curtain box, PVC trucking, cable duct, PVC skirting, PVC protection corner and so on. And by changing screw barrel and mould, it can also produce PVC based WPC products, such as: WPC wall panel, WPC window

PVC window and door profile extrusion line Application:

Window profile, door profile, ceiling wall panel, cable trunking fencem pvc skirting, PVC construction material profile...

Materials: PVC+ calcium powder+wood powder+other additives.

Equipment Features:

For extruder Temperature Control system, Digital PLC control or Manual Temperature Control MeterEasy Operation,Reliable performance, High Extrusion Efficiency, Easy MaintenanceApplication product PVC Profile

1. Self-fire extinguishing, non-flammable. 2. It is inpenetrable by insects and termites, and won't rot or rust. 3. Resistance to weather/ special chemicals, waterproof/washable. 4. The excellent rigid and superior impacted surface is without any peeling. 5. Natural wood grain: showing authentic wood srtucture and artistic sense. 6. Easy to be cut, drilled, nailed, sawet, and riveted. DIY is all right. 7. Quick maintenance and no need of painting. 8. The simple and fast installation can save a lot of time and manpower cost.

Product Parameters

Model | YF180 | YF240 | YF300 | YF400 | YF500 | YF600 |

Max. Product width(mm) | 180 | 240 | 300 | 400 | 500 | 600 |

Max. Product height(mm) | 100 | 100 | 150 | 150 | 150 | 150 |

Extruder model | SNJZ51/105 | SNJZ65/132 | SNJZ65/132 | SNJZ80/156 | SNJZ80/156 | SNJZ80/156 |

Vacuum pump | 5.5kw*2 | 5.5kw*3 | 5.5kw*4 | 5.5kw*4 | 5.5kw*4 | 7.5kw*2+5.5kw*2 |

Water pump | 4kw*1 | 4kw*1 | 4kw*1+2.2kw*1 | 4kw*1+2.2kw*1 | 4kw*1+2.2kw*1 | 4kw*1+2.2kw*1 |

Hual-off motor | 1.1kw*2 | 3kw | 3kw | 2.2kw*2 | 2.2kw*2 | 5.5kw*2 |

Cutter motor | 1.5kw | 2.2kw | 2.2kw | 2.2kw | 2.2kw | 3kw |

Detailed Photos

01 Conical twin screw extruder

• World famous brand electrical component such as Siemens,Schneider, ABB etc; • High torque gearbox with adopts NSK/SKF bearing; • Siemens/WEG original motor achieved global after service; • Bimetallic screw and barrel; • Intelligent PLC controlling system with human-friendly interface.

02 Die head

• 3Cr13/3Cr17 material; • Complete set include extrusion die head, calibrator and cooling tank; • Apply to soft PVC, rigid PVC, soft-hard co-extrusion profile, foamed profile, multi-layers co-extrusion etc.

03 Vacuum calibrating table

• Include full set of vacuum and water pump; • Length from 4m-11.5m; • Independent operation panel for easy operation.

04 Haul off and cutting machine

• Upper and lower caterpillar is driven separately and speed control by frequency inverter;• Fast change type pads for easy operation;• Install plate is adopts aluminum material;• Compacting driving by pneumatic;

• Tracking cutter or lifting saw cutter with adopts double station dust collection system;• Synchronous driving by air cylinder or servo motor control.

Process of Production

Production Flow:

Material →Heating Cooling Mixer →Material Feeding →Conical Twin Screw Extruder →Extrusion Mould & calibrator → vacuum Calibration Table →Printer → Haul-off Unit →cutter →stacker

Final Product

Customer Feedback

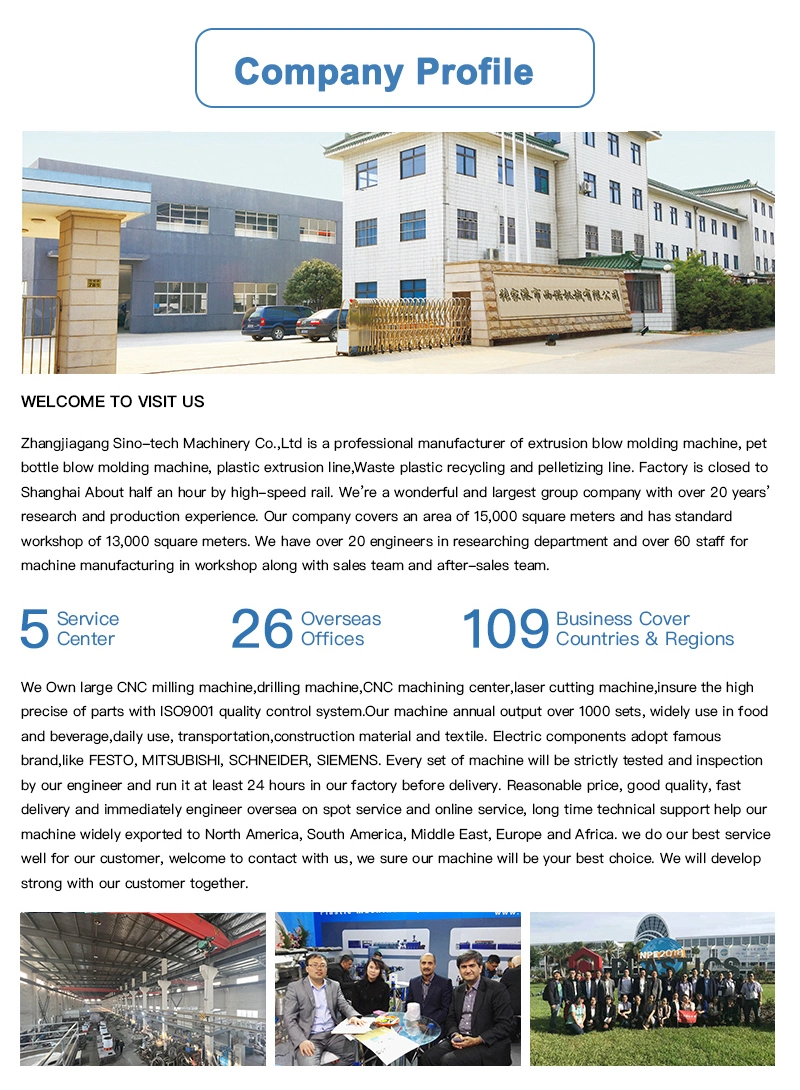

Company Profile

Packaging & Shipping

FAQ

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-60 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees.

Q: What's the advantage of SINOTECH?

We provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time.