High Capacity Dry Cat Food Pet Animal Food Machinery Sinking Floating Fish Feed Pellet Processing Line Dog Food Making Extruder Machine

Basic Info

| Model NO. | HM95 |

| Processing Technics | Mixing-before-Crushing |

| Screen Mesh | With Screen Mesh |

| Grinding Equipment Type | Feed Hammer Mill |

| Pellet Mill Type | Screw Granulator |

| Bulking Machine Type | Twin Screw Bulking Machine |

| Expanding Method | Dry Expansion |

| Condition | New |

| Applicable Materials Shape | Ball |

| Warranty | 1 Year |

| Capacity | 1000-1200kg/H |

| Voltage | 380V, 50Hz, 3phases (Adjustable) |

| Control System | PLC |

| Delivery Detail | 25 Working Days After Receiving Deposit |

| Motor | Siemens, ABB or China Famous Brands |

| Power | 120kw |

| Machine Material | Food Grade Stainless Steel |

| Product Name | Dog Food |

| Need Worker | 2-3 Workers |

| Transport Package | Inside Plastic Bag, Outside Wooden Case |

| Specification | 45000*2500*2500mm |

| Trademark | HIMAX |

| Origin | Shandong China |

| HS Code | 8438800000 |

| Production Capacity | 500sets/Month |

Packaging & Delivery

Package size per unit product 4500.00cm * 250.00cm * 250.00cm Gross weight per unit product 3000.000kg Lead Time 7 days (1 - 1 Sets)30 days (2 - 5 Sets)

To be negotiated ( > 5 Sets)

Product Description

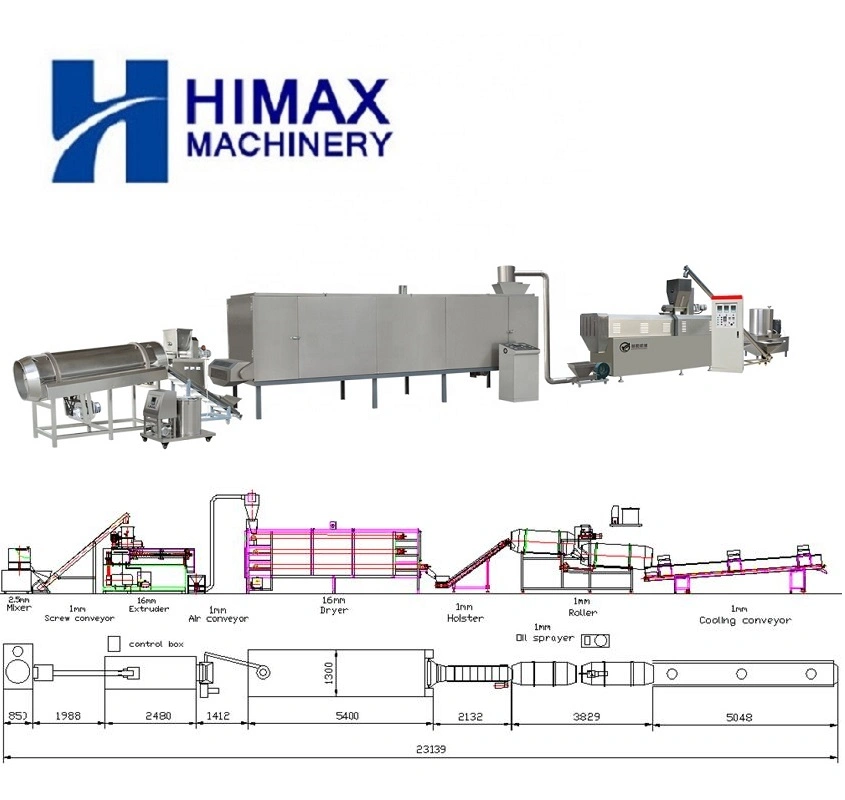

Fully Automatic Stainless Steel Dog Cat Food Extruder Processing Line Pet Food Making Machine

Fully Automatic High Capacity Dry Dog Pet Food Feed Production Line Making Machine with Low Price1.Product Description of Dry Method Pet Dog Food Production Line Making Machine

Dry dog food production line uses foodstuff, meat powder, fishmeal, and beans etc. as raw materials to produce pet food and fish and bird feed with new shape, unique taste, rich nutrition and exquisite structure.

The products are cooked and sterilized with high degree and high pressure of the extruder, so it is easy to be absorbed and popular to the pet market.

- Machine shield: 201 ss / 304 ss as required

- Parts contact with food: 201 ss / 304 ss as required

- Screw/barrel and cutter of the extruder: special alloy to bear high temp and pressure

- Main motor: Siemens brand

- Touch screen: Wenview brand

- Miniature circuit breaker: ABB brand

- Alternating current contactor: ABB brand

- Thermal Relay: ABB brand

- Molded case circuit brake: CHNT brand

- Small relay: Weidmuller brand

- Inverter: Delta brand

- PLC system: Delta brand

- Burner: Baltur brand

2. Technical Parameters of Automatic Dry Dog Food Making Machine

| Model | Installed Power | Consumption Power | Production Capacity | Dimension |

| HM-65 | 70KW | 40KW | 120-150kg/h | 22000*1200*2200mm |

| HM-70 | 90KW | 50KW | 200-250kg/h | 24000*1500*2200mm |

| HM-85 | 120KW | 100KW | 400-500kg/h | 28000*3500*2300mm |

| HM-90 | 96KW | 80KW | 1000kg/h | 30000*3500*2300mm |

| HM-95 | 180KW | 120KW | 1500kg/h | 45000*2500*2500 |

3.Detail of the machine parts of Dog Food Making Machine Pet Food Extruder Machine

| Mixer |

| Screw Conveyor It can be hoisting the mixed material from the mixer into the extruder machine |

Double Screw Extruder | Dryer | ||

Spray-spraying machine | Cooling Machine |

4.Quality Control of Big Capacity Low Price Pet Food Extruder /Dry Dog/Cat/Fish Food Making Machine

5.Packing And Delivery

| Packaging Specification | Outside Package: Wooden Packing as Export and Standard. |

| Delivery time | 20-25days after received 40% of the whole payment. |

| Shipping forwarding | We can be responsible for the shipping,of course, we can also accept and cooperate with your agent if you have a shipping forwarder in China |

6.Company Information

Jinan Himax Machinery is a professional supplier of food processing machines for 12Years. We have many kinds of machines and production lines, such as dry dog food production lines, soya meat production lines, industrial microwave ovens, packaging machines, pet food production importantly, we also provide formulas, technology supports, machine inspection services, etc. Cooperating with different manufacturers and research centers, we provide food processing machines with outstanding quality. We have a group of experienced experts and outstanding engineers who do provide professional service, delivery, and installation. Based on the client's specific requirements, we also have OEM machines for our clients.

7. Our Services

-- Before sale service

1. Provide the free consultation of the equipment.

2. Provide the standard device and the flow chart.

3. According to the clients' special requirement, offering a reasonable plan and free design helping to select the equipment.

--Services during the sales:

1. Help client design the factory and offering professional advice, free engineering drawing for the factory layout

2. Welcome to visit our factory or the domestic clients' factory.

3. Inspect the machine before leaving the factory.

--After-sale services:

1. Oversea install and debug the equipment.

2. Train the first-line operator.

3. Provide the basic formula.

4. Operation/ Service/ Maintenance Manual: Provided In English.

5. 1-2 engineers will be arranged for custom