Basic Info

| Model NO. | Chicken Feed Grinding Mixer |

| Type | Grinding Equipment |

| Processing Object | Forage, Straw |

| Processing Technics | Crushing-before-Mixing |

| Screen Mesh | With Screen Mesh |

| Grinding Equipment Type | Feed Hammer Mill |

| Pellet Mill Type | Screw Granulator |

| Bulking Machine Type | Twin Screw Bulking Machine |

| Expanding Method | Dry Expansion |

| Condition | New |

| Applicable Materials Shape | Pie |

| Product Name | Chicken Feed Grinding Mixer |

| Keywords | Feed Crushing Mixer |

| Material | Carton Steel |

| Materials Size | Powder or Granule |

| Raw Materials | Cereal,Corn,Wheat,Crushed Grass,Stalk, Straw |

| Application | Animal Feed,Poultry Feed |

| Voltage | 220V/380V |

| Types | Forage Equipment |

| Processing Objects | Forage, Straw |

| Weight | 80kg |

| Dispose | Customer′s Requirement |

| Key Selling Points | Long Service Life |

| Video Outgoing-Inspection | Provided |

| OEM or ODM | Accept |

| MOQ | 1 Set |

| Transport Package | Standard Packaging |

| Specification | Customized |

| Trademark | Bestchickencage |

| Origin | Hebei, China |

Product Description

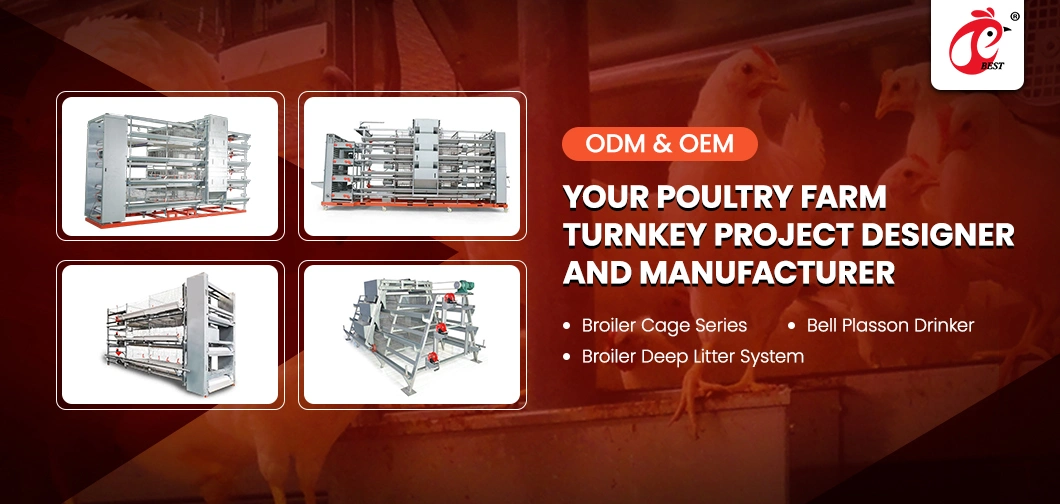

Bestchickencage Feed Crushing Mixer China Feed Grinder And Mixer Manufacturers OEM Customized Environmental Friendly Poultry Feed MixerProduct Description

Many People Have Different Names For Poultry Crushers, Including Poultry Feed Hammer Mill, Poultry Feed Milling Machine, Chicken Feed Milling Machine, Poultry Feed Crushing Machine, Wheat Mill For Poultry Feed, Poultry Feed Making Machine Grinding Mill, Corn Grinder For Chicken Feed, Grain Mills Which Make Poultry Feed, Poultry Feeds Grinding Mills, Poultry Feed Pulverizer, Pulverizer Machine For Poultry Feeds, Etc. Regardless Of The Name, You Just Need To Know That Our Poultry Feed Grinder Machine Is Suitable For All Kinds Of Animal Feed Processing And Suitable For Any Feed Raw Material.Poultry Feed Grinder Machine Is Designed In Large And Small Scale Economical Grinding Equipment For Material Crushing. Also Applies In Areas Such As Food Processing, Brewing, Chemical And Biological. At Present, It Is Mainly Used In The Crushing Process Of Feed Mills Or Farms.

Product Parameters

| Brand Name | Bestchickencage |

| Product Name | Chicken Feed Grinding Mixer |

| Keywords | Feed Crushing Mixer |

| Materials Size | Powder Or Granule |

| Raw materials | Cereal, Corn, Wheat, Crushed Grass, Stalk, Straw |

| Application | Animal Feed, Poultry Feed |

| Types | Forage Equipment |

| Processing Objects | Forage, Straw |

| Core Components | PLC, Gearbox, Motor, Bearing, Engine |

| Voltage | 220V/380V |

Grinder And Mixer Combine Machine Has The Advantages Of Compact Structure, Low Power Consumption, Small Occupied Area, Convenient Loading And Unloading, Less Dust, and Safe And Reliable Work. This Mixer Machine Posses Lower Consumption, Less Area Of Occupancy, Easily To Loading And Discharging.Working Principle:The Feed Is Fed From The Top Of The Feed Crusher. Under The Impact Of a High-Speed Rotary Hammer And The Friction Of the Sieve Plate, The Feed Is Gradually Crushed. Under The Action Of Centrifugal Force, The Feed Passes Through The Sieve Hole Is Lifted Into The Crusher By The Fan, And Discharged From The Outlet Of The Crusher Base

Features1. The Mixing Chamber Is a "W" Horizontal Shell Shape, Double Shafts, And Many Paddles. The Spraying System (Spray Nozzle & Fittings)Which Is On Top Of the Mixer Can Meet Light And Heavy Bulk Density Materials Mixing, Improve The Liquid Atomizing And Prevent From Agglomerating;2. Especially Designed Discharger Has Big Door-Opening Angle And Quick Discharging With Little Residue. Good Tightness And No Products Leakage;3. High Mixing Speed And High Homogeneity. It Makes Materials Mixed And Is Not Influenced For Bulk Density, Filling Degree In State Of Loss Weight;4. It Is Widely Used For Mixing Of Powdered, Granular, Flaky, Blocky, Irregular, And Sticky Materials In The Industries Of Feed, Cereal, Food, Chemicals, Medicines, Pesticides, Etc.

Structure Of Feed Grinder Mixer MachineThis Vertical Poultry Feed Mill And Mixer Grinder Machine Can Be Divided Into Two Parts: Crushing Parts And Mixing Part1. Crushing PartsThe Crushing Parts: There Are Two Ways To Feed The Materials: Self-Priming And Forced Feeding. When The Material Is Sucked Or Sent Into The Crushing Chamber, The High-Speed Rotation Of The Hammer Is Used To Crush The Material, And Use Screens To Ensure The Granularity Of the Crushed Feed. With The Beating Of the Hammer Leaf And The Scrubbing Of The Air, The Raw Materials Will Be Crushed Into Mealiness Or Graininess. The Under The Effect O The Centrifugal Air, The Manliness, Or The Graininess Will Get Into The Impeller Casing Through The Sieve Pore.2. Mixing PartsWhen The Propeller Starts To Rotate, The Small Feed Hopper Impeller Chamber Is Forcibly Sent Into The Conveying Pipeline, And Then Lifted By The Propeller To The Top Of The Mixing Barrel, At Which Time The Material Will Be Evenly Scattered In The Mixing Barrel. The Material Rises And Falls In The Mixing Tank And Rotates Left And Right Continuously To Form A Mixing Process, Thereby Achieving A Uniform Mixing Effect. Company Profile

The Office Address Of Hebei Best Machinery Equipment Is Located In Hengshui, Which Is Called The "Golden Cross Cross" By Mr. Fei Xiaotong, A Social Economist. No. 8, Jinyue Industrial Zone, Huafu Street, Xicheng Industrial Zone, Raoyang County, Hengshui City, Hebei Province, It Was Registered And Established In The Raoyang County Administration For Industry And Commerce Of Hengshui City On June 23, 2016. During The Three Years Of The Company'S Development And Growth, We Have Always Provided Customers With Good Products, Technical Support, And Sound After-Sales Service. Our Company Mainly Operates Production And Sales: Sericulture Machinery, Grassland Construction Machinery, Pasture Harvesting Machinery, Poultry Incubators And Brooders, Poultry Feeding Machinery, Livestock Feeding Machinery, Beekeeping Equipment, Poultry Breeding Machinery, Poultry Product Collection Machinery, And Other Livestock And Poultry Animals Import And Export Business Of Feeding Machinery.

FAQ

1.

Q: Chicken cages can be customized?

A: Yes, We have an A-type chicken cage and an H-type chicken cage now, and all kinds of chicken cages can be customized design according to each client's demands, provide a non-standard design of the program and process flow chart to you.2.

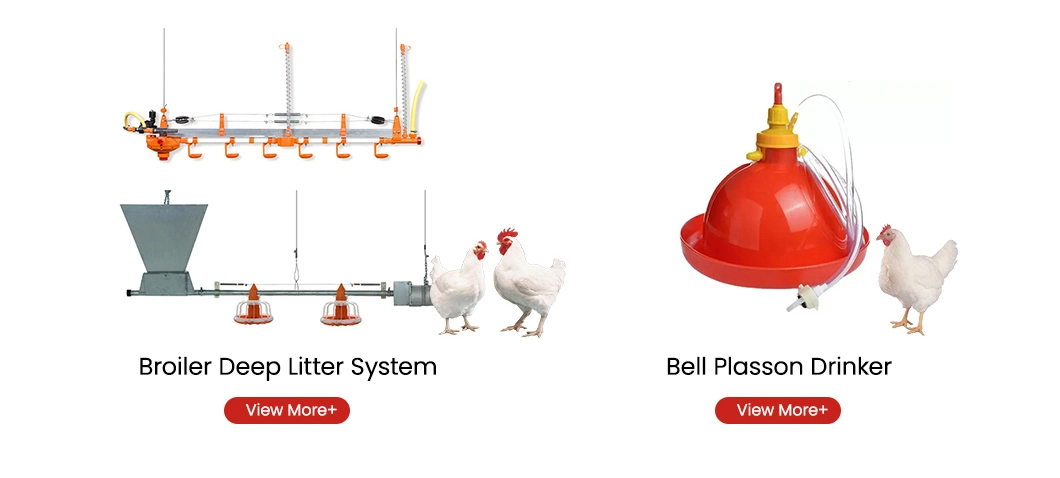

Q: What kinds of chicken cages you can offer?

A: We can produce a cage system, automatic feeding system, automatic egg collecting system, automatic manure removing system, automatic environmental control system, automatic broiler cage, Broiler deep litter system, Bell plasson drinker, breeder cage, layer cage, Egg incubator, Manure drying machine, Scraper manure removal system, Steel poultry house, Ventilation control system. etc3.

Q: what's your payment and currency?

A: We accept different kinds of payment terms: 1) Accept payment of TT. 2) Accept L/C 3) Accept Alibaba credit guarantee payment 4) Westen Union, Paypal. e-Checking, Visa card, Master card, etc.B: The currency we accept have USD, RMB, EUR, GBP, and AUD.4.

Q: What's the MOQ? How many sets of chicken cages for 20 feet container and a 40HQ container?

A: Our MOQ is 40 sets, one 20 feet container can load 80-100 sets, and one 40HQ container can load 160-200 sets of chicken layer cages.5.

Q: What information do I need to provide?

A: Normally, we need our customer to provide below information: 1. Which kinds of chicken do you plan to feed? (layer, broiler, or pullet) 2. How many birds? (5000 birds or more?) 3. Do you need automatic equipment? 4. Do you have a chicken house? (L*W*H) 5. Working voltage? (V, HZ, Phase) 6. Any other requirements you need?