Dairy Farm Feed Processing Machines Vertical Horizontal Type Tmr Fodder Mixing Machine Tmr Mixer

Basic Info

| Model NO. | 9JGW |

| After-sales Service | 1 Year |

| Type | Mixing Equipment |

| Processing Object | Mixed Feed |

| Processing Technics | Crushing-before-Mixing |

| Screen Mesh | With Screen Mesh |

| Grinding Equipment Type | Feed Hammer Mill |

| Pellet Mill Type | Ring Die Pelleter |

| Bulking Machine Type | Sigle Screw Bulking Machine |

| Expanding Method | Dry Expansion |

| Condition | New |

| Applicable Materials Shape | Powder |

| Warranty | 1year |

| Suitable | Manufacturing Plant, Farms, Feed Mill |

| Feature | High Efficiency Low Cost |

| Raw Materials | Corn Stalk, Wheat, Sorghum, Bean |

| Color | Clients′ Requirement |

| Transport Package | Wooden Box |

| Specification | TMR Feed Mixer |

| Trademark | LEABON |

| Origin | Henan, China |

| Production Capacity | 200sets/Month |

Product Description

Dairy Farm Feed Processing Machines Vertical Horizontal Type TMR Fodder Mixing Machine TMR Mixer

Products Description

(1) This product has advanced and reasonable design, the bottom of the trough adopt high quality alloy steel production, safe and reliable work. Made of unique cutting blades with high wear-resistant materials, dragon blade material with high-quality high-alloy steel, thus greatly improving the product's life.

(2) The product is flexible and convenient operation, safe and reliable.

(3) Each feed The mixer can feed 200-2000 cows per day, which can replace more than 20 workers to reduce the labor intensity and improve the feeding efficiency.

Features

1 TMR mixer can directly mix various feeds such as hay, straw, silage.2 When the feed is processed, the coarse fiber will not be destroyed.3 The mixing chamber body has less wear and long service life.4 With automatic weighing device, the amount of addition can be set at any time.5 Feed mixing uniformity is high, energy intake is balanced, and milk production is increased.

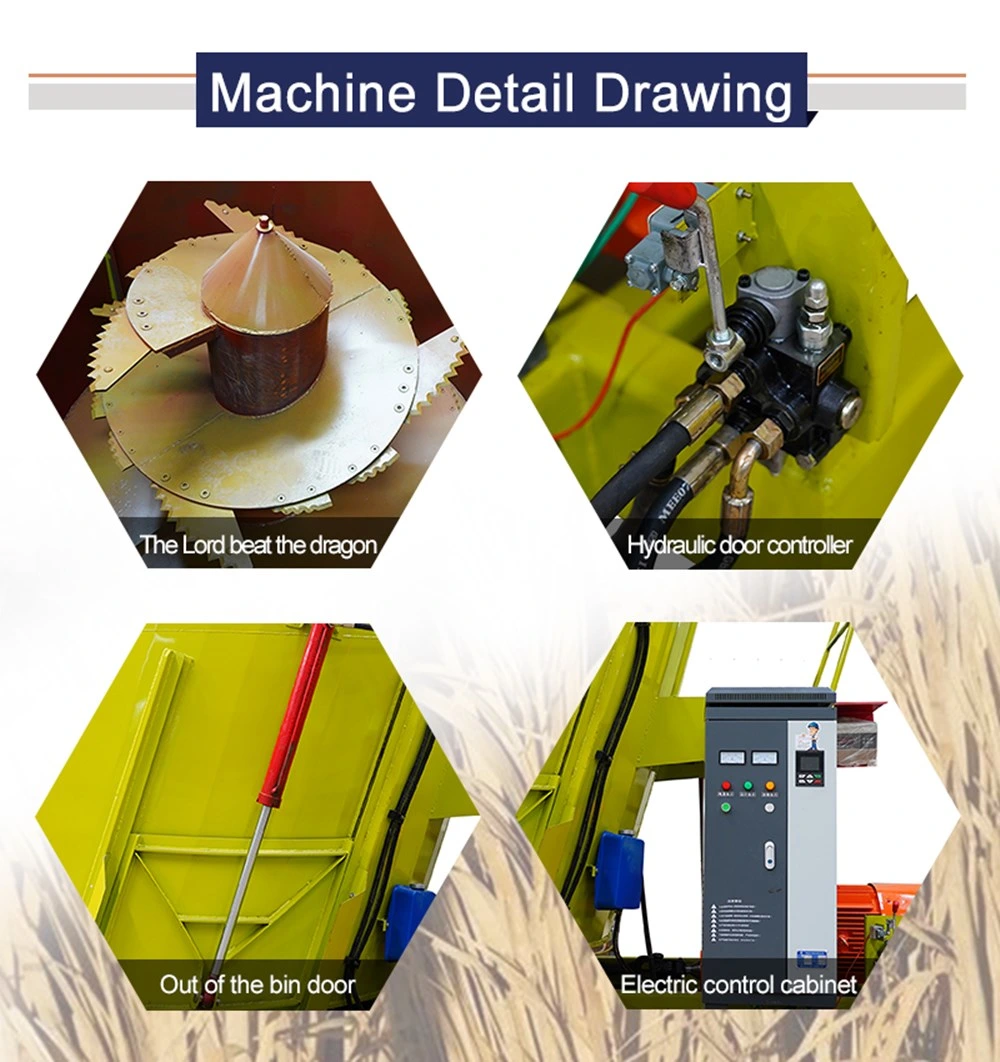

Detail Image

Specification of vertical feed mixer

| Model | 9JGW-13 | 9JGW-10 | 9JGW-5 |

| Overall size(mm) | 4700*1900*2300 | 4200*1900*2300 | 3700*1900*2300 |

| Qty of blade(pcs) | Moving blade 52Fixed blade 8 | Moving blade 42Fixed blade 6 | Moving blade 37Fixed blade 4 |

| Rotating speed(r/min) | 12-16 | 12-16 | 12-16 |

| Weight(kg) | 2600 | 2100 | 1900 |

| Capacity of material hopper(m³) | 13.2 | 10.03 | 5.3 |

| Matching power(kw) | 22-30 | 18.5-22 | 15-18.5 |

| Productuvuty(kg/h) | 5000-7000 | 3800-6000 | 2000-4000 |

Model | LBL-5 | LBL-9 | LBL-12 |

Productivity (t/h) | 2-3 | 4-5 | 6-7 |

Power (kw) | 15 | 22 | 30 |

Mixing Shaft | 1pc major mixing shaft | 1pc major mixing shaft | 1pc major mixing shaft |

Blade Type | Large serrated knife | ||

QTY of Blade (pcs) | 5 | 8 | 8 |

Weighing System | 4 sensors, 1 display | ||

Bottom Plate Thickness (mm) | 14 | 16 | 16 |

Side Plate Thickness (mm) | 5 | 8 | 8 |

Dimension (m) | 3.1*1.9*2.1 | 3.9*2.3*2.5 | 4.6*2.4*2.6 |

Weight (kg) | 1900 | 2800 | 3600 |

Raw Material & Final Product

| 1.Hammer mill | Crushing various kinds of pellet raw material such us corn,sorghum,wheat,bean,wood chip,etc into powder. |

| 2. Feed Mixer | Mixing different kind of powder feed material evenly together. |

| 3. Pellet Machine | Making mixed powder feed into different size feed pellets for different animals |

| 4. Cooler & Screen | Cooling hot feed pellets and screen dust out of pellet to keep pellet clean,for long time storage. |

| 5. Pellet Crusher | Crumbling big size pellet into small size feed pellets for chicken. |

| 6. Rotary Screen | Screening dust out of pellets. |

| 7. Packing Machine | Packing feed pellets into bag for sale/transportation and long time storage. |

Product packaging1.Generally use the export standard wooden for packing , large-scale & production line equipment.2.Can also be based on the specific requirements of customers for packing .Related production:

Our Service1.Customized products and packaging;2.24-hours online inquiring support.3.One year warranty but without the spare parts.4.Video and technical guidance.5.Show our factory and support video inspection.6.Free raw material test service.7.Engineers available to service machinery overseas.FAQQ:I know very little about this machine, How should I make a choose?

A:please tell us your specific requirement, we will offer the most appropriate model for you,you can contact us at any time

Q: What if the spare parts are broken?

A:For each machine,we will have several parts that can be replaced, have a three years warranty on the core parts

Q:I don't know how to install and use it?

A:We will offer video and online instruction.

Q:Do you have a warranty?

A:Yes,we have one year warranty for our products

Q:If the machine has a little mistake when produce and can not solve,what should i do?

A:Please contact us immediately,by email,WeChat,or telephone,our worker will give you the solution.